-

Application Stories

• Building

• Furnace and Boiler Tube Inspection

• Medical

Mastering the Maintenance Process

Mastering the Maintenance Process: Thermography allows Eaton Group to save a quarter of a million dollars per year

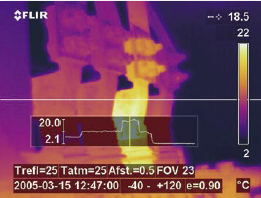

Preventive maintenance is not just a matter of organisation: it also requires knowledge and the efficient handling of gathered information. A suitable thermal imaging camera helps in both of these areas, with an impact which makes itself abundantly clear in the cost-benefit analysis. Thermography, among other things, reveals and measures heat generation in machines and installations. It visualises overheated components and detects and prevents "creeping" breakdowns. It has become a familiar and accepted technique for preventive maintenance. What is less well known, however, is that the consistent, large-scale use of thermography can yield impressive savings.

The American Eaton Group produces a very wide range of industrial goods worldwide, and has a turnover of 9.8 billion dollars. In Europe, its segments Eaton Fluid Power, Eaton Automotive and Eaton Truck are strongly represented. They focus on various systems and com¬ponents for vehicles and for the aviation sector: from hydraulic systems for the new Airbus A380 to compressors for the engines of legendary Italian motorcycle maker Ducati. Eaton Electrical manufac¬tures and modifies low- and medium-voltage distributors and installations for industrial customers.

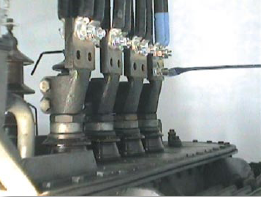

Figure 1. Thermogram/photo pair showing hydraulic system

- Home

- |

- Products

- |

- Training

- |

- Application |

- Image Gallery |

- Contact Us

Copyright ©2012 - Thermoscan Co., Ltd. - All Rights Reserved.

Thermoscan Co., Ltd. (บริษัท เทอร์โมสแกน จำกัด)

731 PM Tower, 5th Floor, Asok Dindaeng Road, Dindaeng, Dindaeng, Bangkok 10400

Tel: (02) 642-9489 Fax: (02) 642-9424

E-mail: tms@thermoscan.co.th