-

Application Stories

• Building

• Furnace and Boiler Tube Inspection

• Medical

Boiler and Furnace Inspection

A wide variety of industries rely on furnaces and boilers for manufacturing processes.

Proper operation of coal-fired and oil-fired equipment is essential in the production of high-quality goods at reasonable cost. Failures cause not only quality problems, they can also shut down an entire process line. Fired tubes in boilers and process equipment are prone to failures from a variety of mechanisms. These include coking that plugs the inside of tubes and impedes product flow, slag build-up on the outside of tubes, clinker damage, under- and over-heating, flame impingement on tubes due to burner misalignment, and product leaks that ignite and cause serious damage to the equipment. Thermocouples can help discover some of these problems, but they are single-point measurement devices, so they can't detect all of them. Inspection ports provide a view of internal parts, but flames, combustion gases, and ash obscure fired tubes and burners when the equipment is operating. Special infrared (IR) cameras can detect most of these equipment problems during operation, and do it at an early stage to prevent failures. This allows an orderly shutdown and component replacement, thereby reducing maintenance costs and production losses.

FLIR GF309 IR CAMERA SEES THROUGH FLAME

•Measure temperatures of burners, tubes, etc.

•Accuracy ±2% or better (±1% from 0 to 100°C)

•Detachable, nickel-coated heat shield included with camera

•Inspect fired tubes for coking and scaling

•See slag and ash build-up inside boilers

•Check burner alignment and flame impingement

•Inspect external parts of firebox

•Ergonomic camera design; pushbutton operation

•Camera can be connected to a central control room via Ethernet

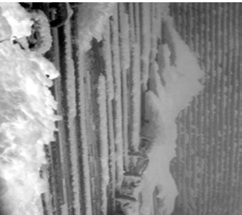

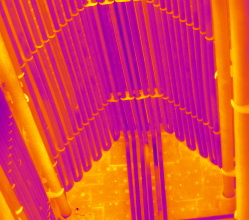

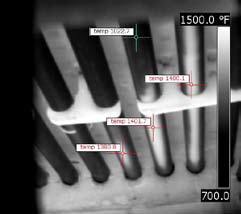

Above: Tubes with ash, slag, and clinker build-up. Center: Overheated tube. Right: Tube coking.

- Home

- |

- Products

- |

- Training

- |

- Application |

- Image Gallery |

- Contact Us

Copyright ©2012 - Thermoscan Co., Ltd. - All Rights Reserved.

Thermoscan Co., Ltd. (บริษัท เทอร์โมสแกน จำกัด)

731 PM Tower, 5th Floor, Asok Dindaeng Road, Dindaeng, Dindaeng, Bangkok 10400

Tel: (02) 642-9489 Fax: (02) 642-9424

E-mail: tms@thermoscan.co.th