-

Application Stories

• Building

• Furnace and Boiler Tube Inspection

• Medical

Neustadt Bayernoil Refinery - Infrared Furnace Camera

A FLIR infrared furnace camera for high temp industrial applications watches hydro reformers at German Bayernoil refinery complex

Stable high temperatures and efficient combustion in refinery furnaces, heaters and boilers are mandatory for a continuous output of high-quality oil derivates. An Infrared camera for industrial high temperature applications in hazardous areas has been developed by FLIR to keep these installations up and running efficiently.

Installations at Bayernoil run at 24/7 and at 100% capacity to satisfy the current high demand for petroleum products. Hence the major importance of condition monitoring and preventive maintenance of furnaces and heat supply.

Super grade petrol and light fuel are the result of a reforming process; after desulphurisation, the refined oil passes into the hydroreformer for a chemical process during which low-octane petrol is converted into high-octane products by stripping the hydrogen out of the hydrocarbons or rearranging the composition of hydrocarbon molecules respectively. The reformer reactors need a constant, 24/7 supply of heat of up to 510 ºC, which is provided by furnaces and carried by heat piping systems.

Inspecting high temperature areas

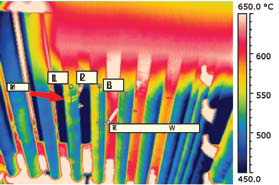

While high temperature thermo elements only allow to measure exactly but very locally, infrared inspection over large surfaces enables to quickly check important parameters for a clean and safe production: are coking, dirt or oxide layers lowering the process temperature? What is the overall operating temperature inside? What is the effect on the surface walls?

Visual and IR image of inner furnace piping.

- Home

- |

- Products

- |

- Training

- |

- Application |

- Image Gallery |

- Contact Us

Copyright ©2012 - Thermoscan Co., Ltd. - All Rights Reserved.

Thermoscan Co., Ltd. (บริษัท เทอร์โมสแกน จำกัด)

731 PM Tower, 5th Floor, Asok Dindaeng Road, Dindaeng, Dindaeng, Bangkok 10400

Tel: (02) 642-9489 Fax: (02) 642-9424

E-mail: tms@thermoscan.co.th