-

Application Stories

• Building

• Furnace and Boiler Tube Inspection

• Medical

SNCF Application Story

The SNCF is one of Europe's largest public transport service companies with 33,000 km of tracks, of which more than 1,500 km are high-speed track for its TGV, Europe's first commercial fast-track train. The public company uses thermography for maintenance purposes to inspect its signaling installations and power stations.

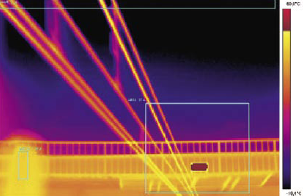

The French national railway company intensively uses thermography to keep its extensive power supply and signalization operations running. SNCF applies thermography for maintenance and uses a FLIR Systems ThermoVision A40-M to inspect overhead catenaries at a speed of 120 km/h, and is now also testing the potential of thermography to inspect its more than 20.000 km overhead wires with a FLIR Systems camera mounted on a test wagon.

Twenty-five ThermaCAMs at Work

The SNCF started to introduce infrared thermography on a large scale after a test inspection of signalization switchboards. The inspection, conducted 2001 in the Strasbourg region (eastern France) revealed that up to 45% of the installations had serious anomalies. This prompted the SNCF to procure four FLIR Systems PM 695 camera systems, a predecessor model of the current P640, and to train ten thermographers.

Convinced by the benefits of thermography, the SNCF acquired twenty-five ThermaCAM E-series handheld cameras for its regional maintenance services. More than 80 SNCF employees now use thermography on a daily basis to conduct their inspection work.

New Applications Demanded

But the SNCF maintenance authorities were faced with problems of another kind. They observed that overhead catenaries of one of the main lines in the Parisian area became often overheated, expanding to such an extent that they almost touched the wa-gons. At first, the maintenance team thought that this was due to the dense traffic on the busy line. However, reinforcing the system's suspension cables and feeders did not solve the problem.

So Gerard Millot, Catenary Maintenance expert at SNCF, decided to turn to thermo-graphy to get a picture of the heating pattern of the catenaries. But how to get a clear and consistent picture of a heating pattern on kilometers of catenaries? The issue became pressing as the SNCF was recording over thirty failures annually due to overheated catenaries. "The scenario is always the same," says Gerard Millot: "the failed connections cause a heating of the contact wire. This wire starts to expand, looses tension and starts to sag. In the worst case, it gets wound up around the locomotive's pantograph. The train stops and the line is blocked. Repairing overhead lines takes time and one can only imagine the consequences on busy lines at rush hour."

First measurement experiments proved that, in order to obtain a satisfactory view on the heating of catenaries, the camera had to be mounted on a wagon. The SNCF engineers also found out that the infrared camera had to be installed on a special measurement wagon which would take electrical current from the contact line on a permanent, uninterrupted basis.

- Home

- |

- Products

- |

- Training

- |

- Application |

- Image Gallery |

- Contact Us

Copyright ©2012 - Thermoscan Co., Ltd. - All Rights Reserved.

Thermoscan Co., Ltd. (บริษัท เทอร์โมสแกน จำกัด)

731 PM Tower, 5th Floor, Asok Dindaeng Road, Dindaeng, Dindaeng, Bangkok 10400

Tel: (02) 642-9489 Fax: (02) 642-9424

E-mail: tms@thermoscan.co.th