-

Application Stories

• Building

• Furnace and Boiler Tube Inspection

• Medical

Waste Bunker Management

Solid waste management is a crucial sector in our consumer society. It is a USD 43- billion-industry and growing as more regions experience positive economic growth and prosperity and consequently produce more household waste. At the same time, legitimate environmental concerns push for an increasingly streamlined waste disposal, treatment, neutralization and recycling process. The waste has to be gathered, stored and processed. As supply (in this case places for storage or processing of waste) is scarce and demand is increasing, economic laws of market and efficiency increasingly apply to waste management.

In densely populated West-European countries, solid household waste is collected and carried to a waste incineration plant, rather than dumped directly in landfill sites. The most advanced incineration plants use the combustion heat to fuel up an adjacent waste-to-energy system, which provides heating and power to nearby residential areas.

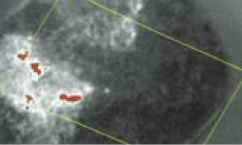

The waste is therefore stored in so-called waste bunkers, which contain thousands of metric tons of solid waste. This waste is potentially flammable when stored: self-combustion, heat development due to pressure, spontaneous chemical reactions between the disposals, methane gas-building, are potential fire creators. Waste bunker fires can be hazardous for both operator and environment: the heavily contaminated firefighting water, which hampers the further processing of the waste, has to be disposed as well. And firefighting does not always reach potential fire spots still dangerously smoldering somewhere in the large and deep bunker. This is why the stored waste has to be permanently moved, mixed and turned by crane operators.

Twenty-five ThermaCAMs at Work

The need for fire prevention becomes even more acute for installations with a waste shredder: sparks from shredding metal and other solid parts compound with methane gases, resulting in an explosive cocktail scattering around the entire waste bunker. Consequently, fire prevention and fire detection are important issues for waste storage and management. While most national or regional legislators stipulate that fire prevention ought to be taken by the public or private plant operator, they generally do not clearly state how.

Infrared cameras are excellent tools for both fire prevention and fire detection, provided they offer some basic features that serve the purpose:

• the ability to detect and clearly visualize nascent hot spots through smoke/dust

• measure and indicate temperature

• control pre-defined areas on a permanent basis

• raise an alarm when a temperature threshold is passed

Fire prevention systems are installed by specialized system integrators. One such leading integrator on the market is the high-tech company m.u.t GmbH, based near Hamburg, Germany. m.u.t. develops and markets photonics products for complex solutions in the medical, aerospace, security and other sectors, and has specialized, among other things, in early fire detection for air and land transportation carriers and waste incineration plants. m.u.t. offers a complete solution including planning, installation, software, hardware, and maintenance. It has installed more than forty infrared camera-based early fire detection systems in waste bunkers across Europe. "Preliminary planning is the hardest part of the job", says Werner Hagedorn, Account Manager for the early fire detection products, "we have to define the best place to install the camera, divide the entire waste bunker in zones and ensure that for example the minimum surface of 30x30 cm to detect hot spots that is advised by some regional legislators, is covered by the camera."

- Home

- |

- Products

- |

- Training

- |

- Application |

- Image Gallery |

- Contact Us

Copyright ©2012 - Thermoscan Co., Ltd. - All Rights Reserved.

Thermoscan Co., Ltd. (บริษัท เทอร์โมสแกน จำกัด)

731 PM Tower, 5th Floor, Asok Dindaeng Road, Dindaeng, Dindaeng, Bangkok 10400

Tel: (02) 642-9489 Fax: (02) 642-9424

E-mail: tms@thermoscan.co.th