-

Application Stories

• Building

• Furnace and Boiler Tube Inspection

• Medical

Critical Vessel Monitoring

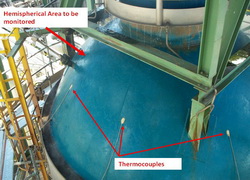

Many fluid vessels, such as chemical reactors, storage tanks, and piping systems, need to be monitored to spot abnormal temperatures and trends that warn of product loss or unsafe conditions.

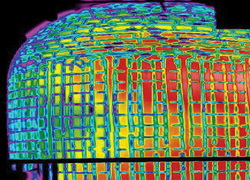

Traditionally, this has been accomplished with point contact temperature sensors such as thermocouples or RTDs. Since individual sensors only monitor "pin point" areas, there is always a concern about non-uniform temperatures throughout a vessel and across its surface. FLIR's Critical Vessel Monitoring (CVM) Systems offer a better solution. A few IR cameras can observe and measure the temperature of the entire vessel surface, sending real time images and alarms to a control room. This application flyer describes how these systems can be designed and used to prevent huge monetary losses due to spoiled product, or worse yet, explosions, fires, loss of life, and production downtime.

REMOTE MONITORING OF CRITICAL VESSELS

• Great for monitoring compost piles, landfills, scrap bunkers, rail hopper cars, etc.

• Non-contact temperature measurement

• Spots problems without onsite personnel

• A few cameras cover entire vessel surface

• Eliminates or minimizes point contact sensors

• Helps detect abnormal process variations before product is ruined

• Earliest possible warning with trend analysis software

• Complements other fire and explosion prevention systems

• Also used for torpedo (submarine) car monitoring

• Works day or night – 24/7 operation

How It Works

Infrared radiation (IR) is emitted by all objects at temperatures above absolute zero, and is detectable by IR cameras. Smart IR cameras (those with built-in logic, memory, and data communications) can compare the temperatures obtained from their thermographic images with user-defined settings for critical vessels. Since these cameras have various means of communicating thermo-graphic images and temperatures to remote locations, they are ideal for unattended monitoring of chemical reactors, storage tanks, and other critical vessels. With camera firmware and/or computer software, they can spot dangerous temperatures and abnormal trends to help prevent product loss and improve safety.

Improved Temperature Monitoring

This approach to critical vessel monitoring (CVM) eliminates or minimizes the installation of point contact temperature sensors such as thermistors, thermocouples, RTDs, or solidstate devices. Since individual sensors can only monitor "pin point" areas, there is always a concern about non-uniform temperatures throughout a vessel and across its surface. It's always a bit of guessing game whether contact sensors are placed in the correct location relative to process flows and reaction locations. A few IR cameras eliminate this concern by monitoring the entire vessel surface, providing instantaneous non-contact temperature measurements. Their firmware allows them to output a digital signal for alarm and control purposes, while also providing live thermographic images.

- Home

- |

- Products

- |

- Training

- |

- Application |

- Image Gallery |

- Contact Us

Copyright ©2012 - Thermoscan Co., Ltd. - All Rights Reserved.

Thermoscan Co., Ltd. (บริษัท เทอร์โมสแกน จำกัด)

731 PM Tower, 5th Floor, Asok Dindaeng Road, Dindaeng, Dindaeng, Bangkok 10400

Tel: (02) 642-9489 Fax: (02) 642-9424

E-mail: tms@thermoscan.co.th