-

Application Stories

• Building

• Furnace and Boiler Tube Inspection

• Medical

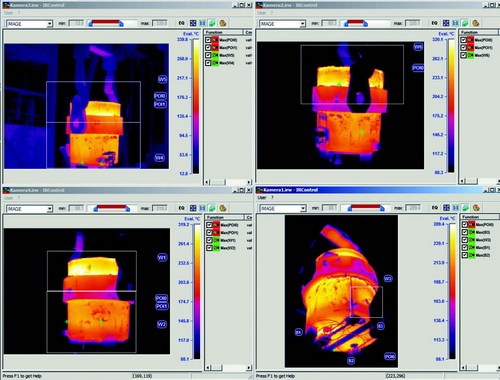

Steel Mill Monitoring

Steel mill ladles have limited lives. As their refractory linings wear or develop breaks due to shock, the outer part of a ladle can be exposed to excessive temperatures. If not caught in time, the result can be ladle disintegration and a molten metal breakout, threatening the lives of workers and destroying equipment. FLIR infrared camera systems are used to monitor ladles in real time and warn of a breakout before it happens. This application flyer describes how these systems can be designed and used to save mills hundreds of thousands of dollars by preventing injuries, equipment damage, and production downtime.

MILL LADLE REFRACTORY MONITORING

• Non-contact temperature measurement

• Remote monitoring from a safe location

• A few cameras cover entire ladle surface

• Ethernet & fiberoptic communications minimize noise problems

• Temperature readings warn of potential molten metal breakout

• Even earlier warning with trend analysis software

• Allows timely replacement of refractory lining before failure

• Also used for torpedo (submarine) car monitoring

• Enclosures available for mill environments

Ladle Safety

It is well known that refractory linings in steel mill ladles have limited lives, and useful life may be shortened even more due to breakage of refractory bricks from mechanical shock. As the lining wears or develops breaks, the outer part of a transport ladle can be exposed to molten metal. If not caught in time, the result can be ladle disintegration and a molten metal breakout, threatening the lives of workers and destroying equipment. Fortunately, IR cameras can detect hot spots on the ladle that warn of a failure far sooner than a visual inspection. This allows the ladle to be taken out of service in a timely manner and scheduled for relining – not too soon, not too late – at the optimum replacement cost.

Ladle Monitoring System

FLIR's approach to ladle monitoring is to place its IR video cameras in robust housings, and locate them in fixed positions where they have a clear view of a filled ladle as it passes by on the gantry crane. Those cameras capture video images of the ladle in real time, and calculate temperatures over the ladle's surface. A few cameras can cover the entire surface of the ladle, but typically a few regions of interest (ROIs) are predefined for closer scrutiny and analysis. The IR images of ROIs where failures are more likely to occur can be stored in PC memory for later comparison to current images. Defining ROIs also allows FLIR'S IR MONITOR software to ignore high temperatures on objects around the ladle that are within the camera's field of view (FOV), which prevents false alarms.

- Home

- |

- Products

- |

- Training

- |

- Application |

- Image Gallery |

- Contact Us

Copyright ©2012 - Thermoscan Co., Ltd. - All Rights Reserved.

Thermoscan Co., Ltd. (บริษัท เทอร์โมสแกน จำกัด)

731 PM Tower, 5th Floor, Asok Dindaeng Road, Dindaeng, Dindaeng, Bangkok 10400

Tel: (02) 642-9489 Fax: (02) 642-9424

E-mail: tms@thermoscan.co.th